When a torque wrench delivers hundreds of hammering blows deep inside a refinery or offshore platform, one silent hero takes the impact: the socket.

To the untrained eye, it is just a chunk of metal. But to metallurgists and engineers, it is a masterpiece of chemistry, heat, and structure designed to survive stress levels that would shatter ordinary steel.

For industrial users across Europe, America, and Asia, from turbine maintenance crews to offshore bolting specialists, understanding the metallurgy behind an impact socket is not trivia. It is the difference between reliable torque and catastrophic failure.

The Steel Behind Strength: Chrome Molybdenum (Cr-Mo)

Every impact socket begins with its foundation in Chrome Molybdenum steel (Cr-Mo). This alloy is engineered to balance hardness, ductility, and fatigue resistance for extreme-duty use.

• Chromium (Cr): Adds hardness, wear resistance, and corrosion protection.

• Molybdenum (Mo): Boosts strength at high temperatures, crucial when working on hot systems or in harsh industrial conditions.

• Carbon (C): Provides the backbone of hardness after heat treatment.

Compared to the more common Chrome Vanadium (Cr-V) used in hand tools, Cr-Mo steel offers superior shock absorption. It flexes microscopically under impact rather than cracking, making it the preferred alloy for safety-critical bolting in refineries, wind farms, and power plants.

Did you know? Cr-Mo alloys (SAE 4140/4340) are the same steels used in aircraft landing gear and oilfield drill collars—components that simply cannot fail.

Heat Treatment: Where Toughness Is Forged

Steel alone does not make a great socket. Controlled heat transforms it into a powerhouse.

After forging, the raw blanks undergo a carefully sequenced heat treatment process:

• Quenching: Rapid cooling locks in hardness.

• Tempering: Reheating relaxes internal brittleness while restoring ductility.

• Stress relieving: Removes residual stress from machining and forging.

This balance yields a Rockwell hardness of 38–44 HRC, tough enough to resist deformation yet elastic enough to survive thousands of torque cycles.

It is here that a socket’s true DNA is written; one that resists both fracture and fatigue.

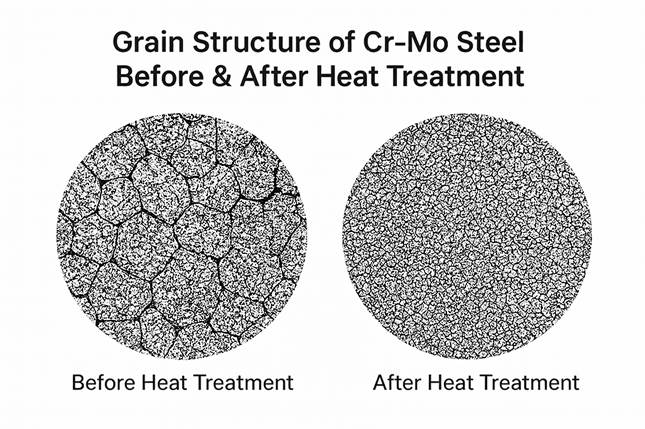

Microstructure: The Hidden Engine

Inside every premium socket lies a fine-grained, tempered martensitic microstructure that is invisible to the naked eye but vital to its survival.

A uniform grain structure prevents cracks from forming or spreading under cyclic stress.

Each impact from a wrench transfers immense localized force, and this fine grain, shaped by alloying and forging, absorbs and redistributes that energy.

Think of it as an invisible shock-absorbing network—steel’s equivalent of muscle fibers flexing under load.

Surface Treatment: Protection with Purpose

Even perfection needs protection.

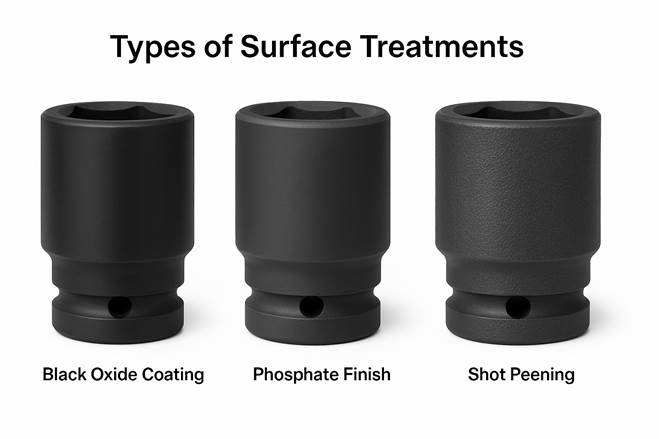

Once the internal structure is engineered, the surface receives coatings that defend against corrosion, abrasion, and glare.

• Black Oxide Coating: Prevents rust and reduces reflection.

• Phosphate Finish: Enhances wear resistance and oil retention.

• Shot Peening (in high-end sockets): Bombards the surface with micro-spheres to induce compressive stress, extending fatigue life by up to 25 percent.

These treatments are vital for sockets exposed to moisture, salt, and industrial chemicals, especially in shipyards, offshore rigs, and energy facilities.

Standards and Compliance: The Proof of Integrity

Behind every professional-grade socket lies a series of global standards that certify performance and safety:

• DIN 3129: Heavy-duty socket requirements

• ISO 2725 / 1174: International square-drive standards

• EN 10277: Steel classification and quality

• REACH and RoHS: Environmental and chemical safety compliance

Manufacturers such as Ozat, a globally trusted brand, go beyond these benchmarks by batch-testing for impact resistance, torque cycle endurance, and metallurgical consistency to ensure field safety even under extreme torque and vibration.

Design Meets Metallurgy

Metallurgy does not stop at composition; it informs design. Every contour of an impact socket reflects metallurgical science:

• Radiused corners reduce stress points.

• Thicker walls allow higher torque loads.

• Optimized broaching ensures tighter fitment and uniform load distribution.

Each feature enhances the socket’s ability to withstand repeated impact without failure—a seamless union of material science and mechanical design.

Conclusion: The Science Inside Every Strike

An impact socket may look simple, but its resilience is born of forging fire, microstructural precision, and metallurgical mastery.

From alloy selection to surface finishing, each step determines how that socket will perform when the stakes are highest—inside a turbine hub, a pipeline manifold, or an automotive assembly line.

When safety, precision, and reliability matter, metallurgy is not an option; it is the foundation.

That’s why Ozat sockets, made from Cr-Mo steel and built to meet global standards, deliver dependable performance where it counts the most.

Leave a Reply