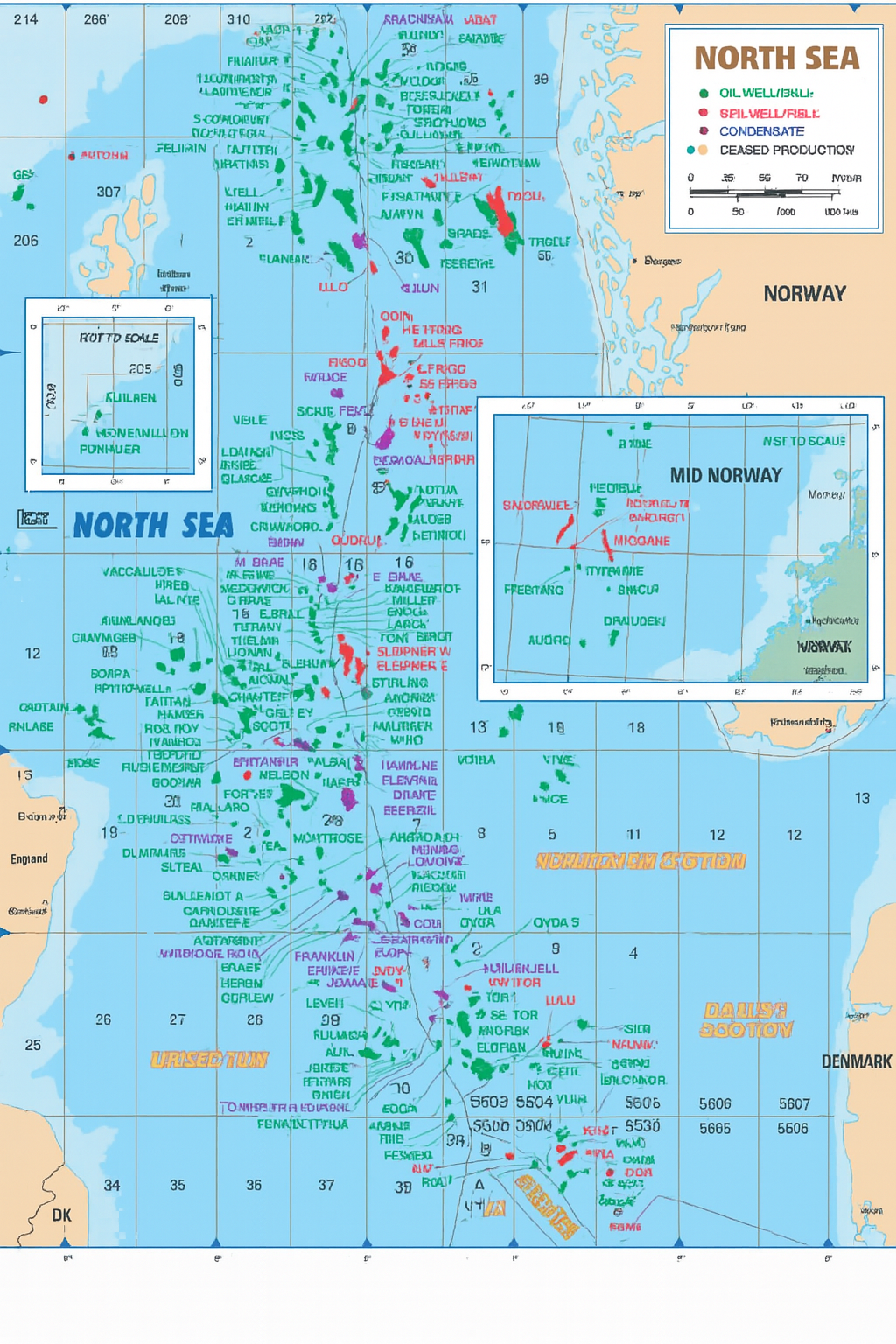

Despite the relentless assault from 10,000 psi pressures below the seabed to storms that generate wave forces exceeding 1,000 KN on platform structures, the North Sea has seen over 20,507 offshore oil and gas wells drilled since the 1960’s, creating a vast network of operations that forms the cornerstone of Europe’s energy landscape.

Constant exposure to high pressures, extreme weather, and corrosive saltwater makes maintaining structural and operational integrity a relentless challenge. In such demanding scenario, the need for reliable, heavy-duty tools has never been higher. Among these essential tools, chrome molybdenum (Cr-Mo) heavy-duty impact sockets stands out as critical components for precision bolting applications.

The Environment: Why the North Sea Requires More

Salt-laden winds, sub-zero winters and unrelenting hydrostatic pressure define the everyday environment of the North Sea. Every offshore asset here, from sub-sea pipelines to FPSOs (Floating Production Storage and Offloading units), operates in conditions that push material and mechanical limits. In these waters, bolting integrity is life-critical. A single failed connection can trigger hydrocarbon leaks, environmental hazards or multimillion-pound shutdowns.

The scale of the challenge is staggering. The UK Oil and Gas Authority (OGA) reports that operators spend over £1.3 billion annually on asset integrity and maintenance across the UK Continental Shelf (UKCS). A significant share of this budget is dedicated to high-performance tools certified to rigorous European standards — ISO 2725, EN 1665, and CE compliance — where reliability under maximum torque is mandatory.

Why Chrome Molybdenum Impact Sockets Dominate?

Chrome molybdenum (Cr-Mo) heavy-duty impact sockets are engineered specifically for hostile offshore service.

With high tensile strength, toughness under shock loads, and superior corrosion resistance, Cr-Mo sockets outperform conventional carbon steel. Protective black phosphate or black oxide finishes further resist saltwater exposure. Paired with pneumatic and hydraulic torque wrenches, they deliver precise, repeatable torque values essential for controlled bolting procedures on live assets.

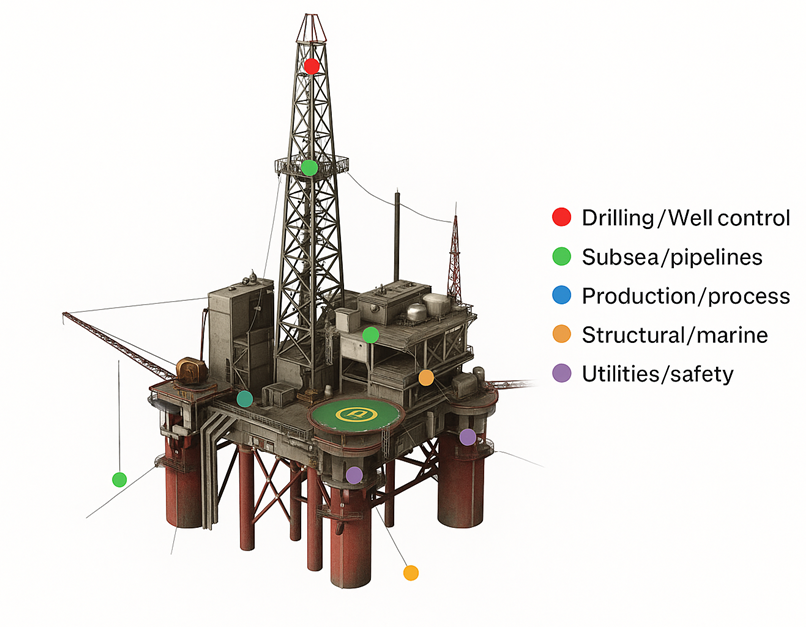

Critical North Sea Applications

• Flange bolting on high-pressure pipework: Securing risers, manifolds, and process lines with 1″ and larger drive Cr-Mo sockets to maintain leak-free, high-integrity systems.

• Blowout Preventer (BOP) assembly: Deploying 6-point and 8-point heavy-duty sockets to maintain well control equipment where failure tolerance is zero.

• Platform crane maintenance: Torquing large structural fasteners in cranes that handle all offshore lifting and logistics.

• Sub-sea template installation: Utilizing deep impact sockets for reliable fastening of seabed guide frames and templates under challenging sub-sea conditions.

• Turnarounds and shutdowns: High-torque rated impact sockets enable fast, safe, and accurate bolting during time-critical maintenance windows.

Sourcing Reliable Impact Sockets

While several manufacturers serve this demanding industry, Ozat Tools has earned trust across Europe and beyond for its range of heavy-duty impact sockets built for oil and gas applications. Ozat’s Cr-Mo sockets offer durability, precision, and compliance with relevant European norms, supporting both offshore and onshore operations.

Future Demand Driven by Energy Transition

As the North Sea pivots to offshore wind, carbon capture and hybrid energy projects, offshore infrastructure is being retrofitted and repurposed. Each modification involves high-torque bolting, further increasing the demand for reliable impact sockets. With over £16 billion forecast for asset decommissioning in the next decade (Oil & Gas UK), the market for precision bolting tools will continue to expand.

Leave a Reply