Oil and Gas Industry

Reliable tools for extreme operations – OZAT sockets enable secure bolting from offshore platforms to refinery floors, where every connection counts in high-pressure environments.

The oil and gas sector is defined by pressure, depth, heat, and corrosion. Tools must endure without fail, from drilling platforms to refineries. OZAT sockets meet these demands with strength, compatibility, and protective finishes—empowering crews to perform bolting in extreme, often remote, conditions across upstream, midstream, and downstream operations.

Applications

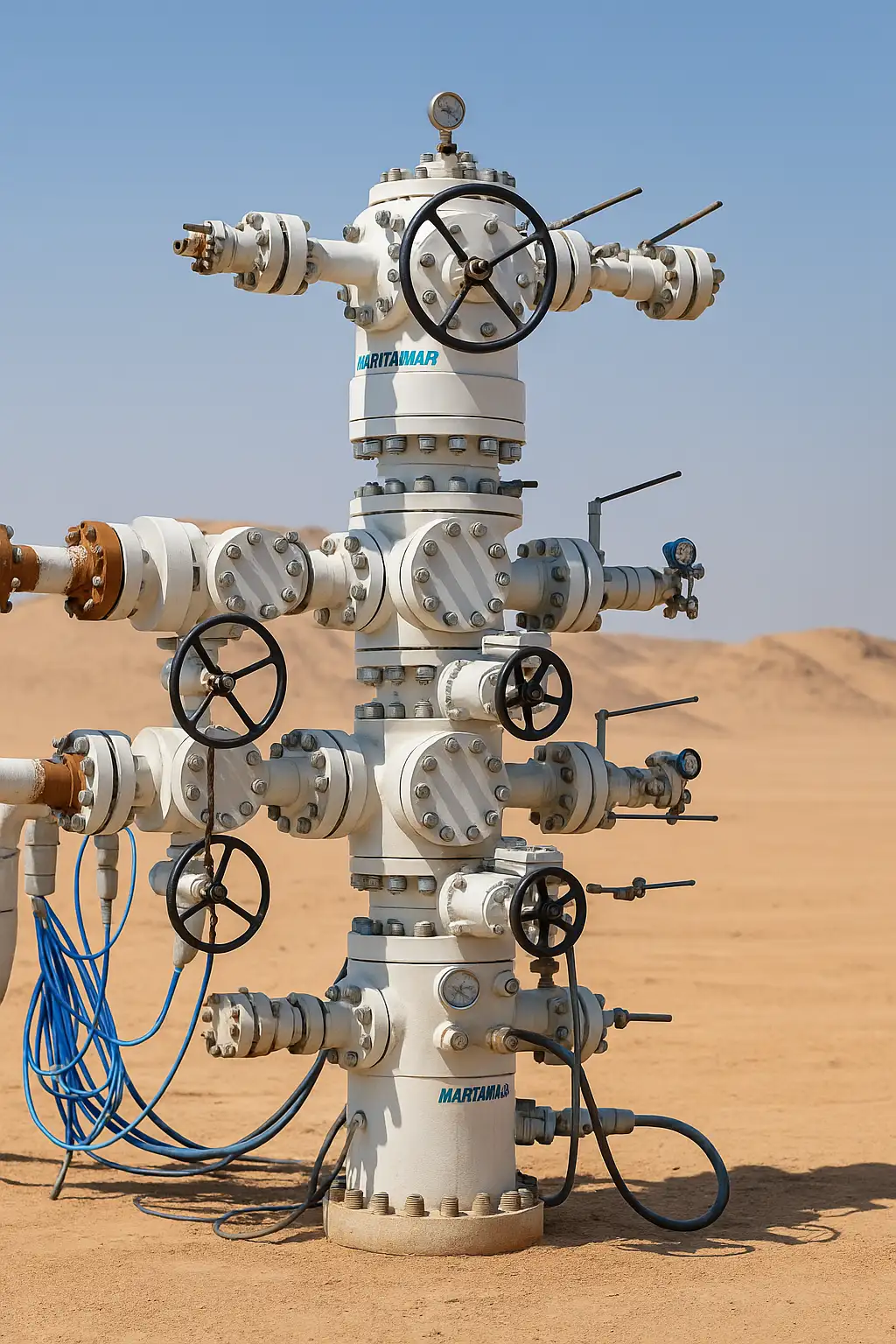

Drilling Rigs & Wellheads

OZAT’s 3-1/2″ drive sockets are used for high-load bolts on risers, blowout preventers, and rotating equipment in land and offshore drilling.

Pipeline Flanges

Technicians tighten large flange assemblies using OZAT 6-point sockets. Their strength ensures uniform bolt stress and integrity under pressure cycles.

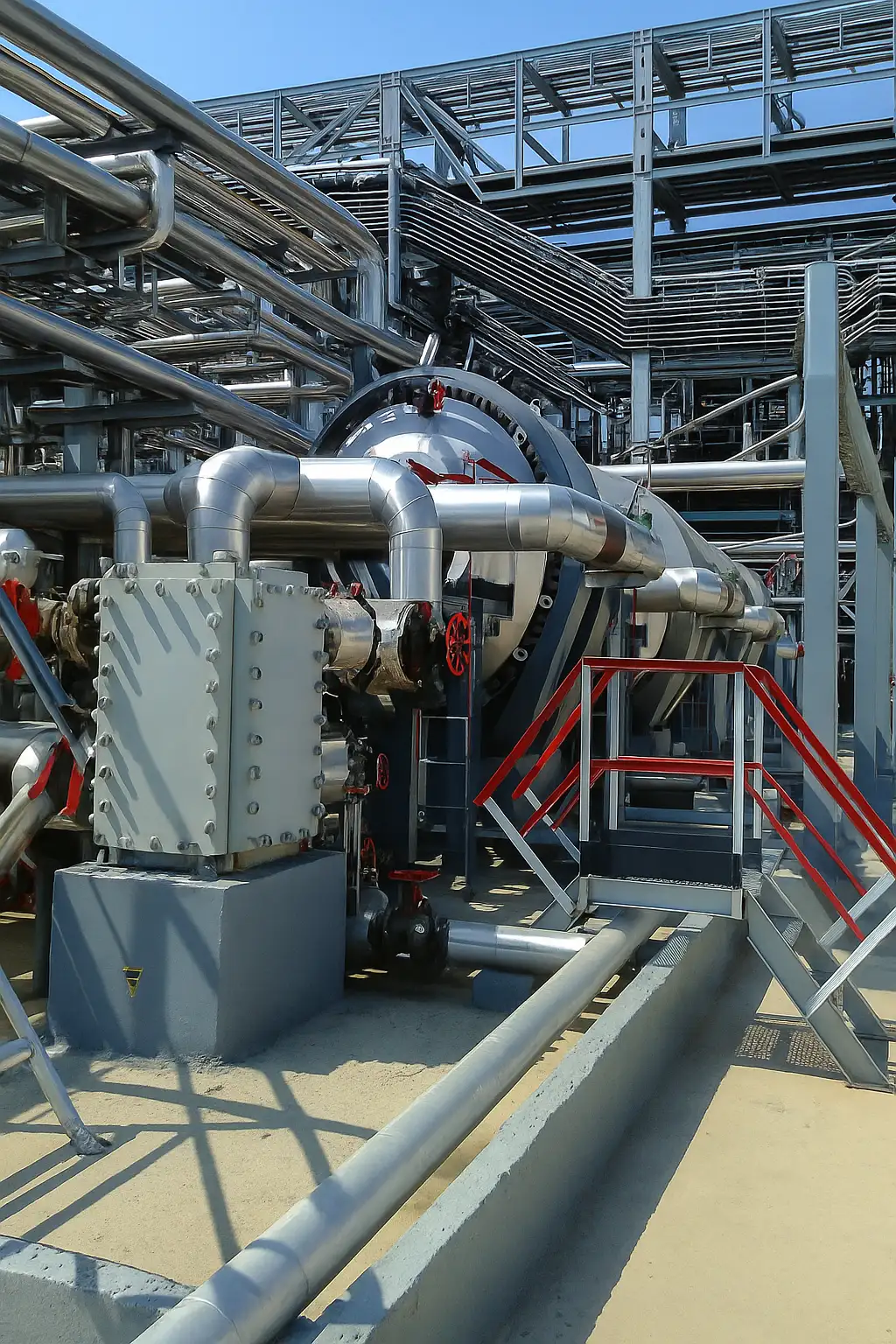

Refinery Maintenance

Non-sparking and deep sockets ensure safe maintenance in flammable zones, supporting valve overhauls, vessel access bolts, and pump connections.

Offshore Operations

OZAT corrosion-resistant sockets and attachments ensure maintenance of marine cranes, platform flanges, and piping bolts under salt spray and splash zone conditions.

Engineered for the Harshest Conditions

Get in touch with OZAT for socket solutions designed to thrive under pressure in oilfields, platforms, and refineries.