A single stubborn bolt can bring an entire industrial operation to a standstill. Whether it’s during scheduled maintenance or in the middle of critical production, one seized or damaged fastener can mean costly delays, safety risks, and frustrated teams. That’s where the right impact sockets prove their worth. Built to handle extreme torque and unforgiving conditions, they ensure that every fastening and loosening job gets done safely, efficiently, and without unnecessary downtime.

Impact Sockets: Critical Components, Not Just Accessories

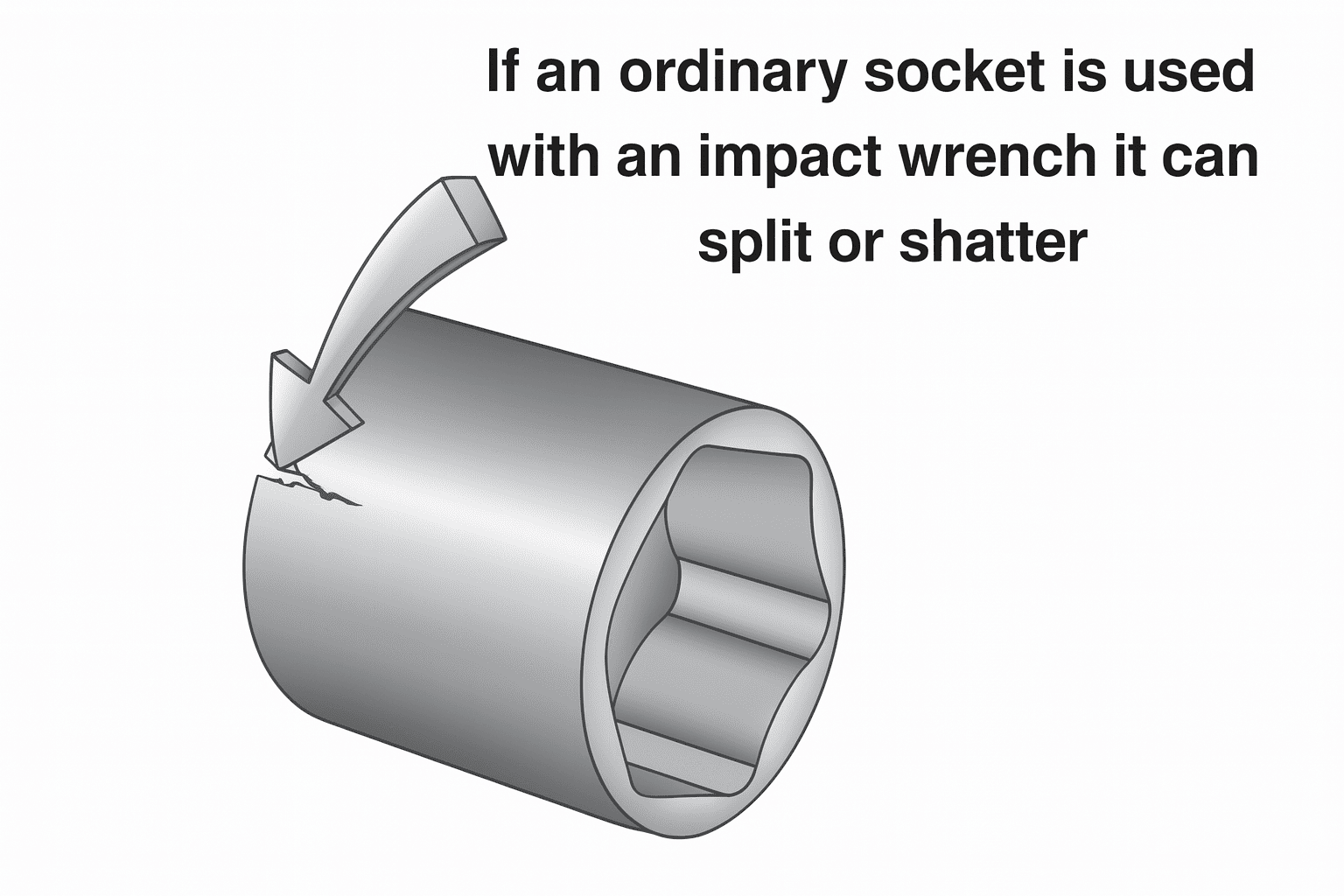

In industrial environments, impact sockets should never be viewed as optional add-ons. They are precision-engineered components designed to protect both equipment and operators in high-torque applications. Unlike standard sockets, which are typically made from harder but more brittle chrome vanadium, impact sockets are constructed from stronger alloys such as chrome molybdenum. This gives them the toughness and flexibility needed to absorb shock loads without cracking.

Impact sockets are also designed with thicker walls, deeper recesses, and specialized finishes that resist wear, rounding, and corrosion. Where a regular socket might shatter or strip a fastener, an impact socket maintains structural integrity under repeated stress. This fundamental engineering difference is why they are trusted for heavy-duty applications like pipeline maintenance, construction, shipbuilding, and power plant operations—where failure is not an option.

Key Pain Points Solved by Impact Sockets

Industrial fastening pushes tools to extremes, and impact sockets are built to meet these demands:

- Seized or corroded bolts: Require controlled bursts of high torque that would crack standard sockets.

- Repetitive torque cycles: Assembly lines and maintenance involve thousands of shocks that only impact-rated sockets can endure.

- Heavy-duty fastening: Structural bolts on turbines, pipelines, or machinery need sockets that deliver extreme torque without deforming.

- Fastener integrity: Impact sockets prevent rounding and stripping, protecting critical components.

- Operator safety: Regular sockets can shatter under load. Impact sockets flex and absorb energy to avoid catastrophic failure.

By solving these challenges, impact sockets turn high-risk fastening into safe, reliable operations.

How does Impact Sockets Outperform Standard Sockets?

Undergoing specialized heat treatment processes that balance hardness with ductility, chrome molybdenum (Cr-Mo) offers superior toughness and flexibility under shock loads without fracturing. High-quality impact sockets are coated with black oxide or phosphate finishes to resist corrosion, especially in humid or chemical environments. Impact sockets are manufactured to meet rigorous standards such as ANSI, ASME, DIN and ISO, guaranteeing safety, dimensional accuracy, and performance under extreme torque. Standard sockets may not undergo the same level of compliance testing, making them unsuitable for industrial impact use.

Safety and Compliance: Engineered for Protection

According to the IHSA (Industrial Health & Safety Association, Canada), using standard sockets with impact tools is a critical hazard. The dangers of using the wrong sockets go beyond breakage. Shattering creates sharp, high-velocity projectiles. Rounding off fasteners can seize assemblies and cause costly downtime. Repeated stress can also create hairline cracks that weaken the socket and fail without warning, while poor fit leads to loss of torque transfer and faster wear on bolts.

Effect of using Standard Sockets with an Impact Wrench

To prevent such failures, best practice requires regular inspection and timely replacement of worn sockets. Signs like spider-web cracks, chipped surfaces, or rounded edges mean immediate removal from service. By following ANSI/ASME markings, OSHA requirements, and HSE guidelines.

Impact sockets, by contrast, carry safety certifications, stamped markings, and often color-coded identification, ensuring workers can instantly confirm they are using the correct tool for high-torque applications engineered to defend against injury and unplanned downtime.

Conclusion

Impact Sockets are engineered safeguards that ensure every bolt is tightened or loosened with precision, reliability, and safety. Choosing them means fewer breakdowns, reduced risk of injury, and uninterrupted productivity.

Takeaway: Cutting costs on sockets is a false economy. Standard sockets may appear cheaper, but their failures lead to downtime, equipment damage, and compliance risks that cost far more. By investing in certified, high-quality impact sockets, industries secure a measurable return—greater safety, higher efficiency, and long-term operational resilience.

Leave a Reply